| Howdy Ya'll |

|

|

Do what yer' Momma said...

Go Play! |

|

| Disclaimer |

|

This website contains Affiliate Links. Please read the Disclosure for details.

|

|

|

|

Fiberglass 101 |

Share on:

|

|

|

Filling in the Cracks

I've decided to share what I have learned in my crack filling episodes where the fiberglass

meets the metal, namely the elevators, rudder and horizontal stabilizer. I don't claim to be

an expert, but an adventurer, picking the brains of those who have covererd their cracks (he-he)

in the past. You'll notice that the pictures below are from different parts of the airplane.

That's because I'm the world's worst at remembering to take pictures!

Let's get started:

I ordered my fiberglass supplies from

Amazon.com

and Aircraft Spruce.

I also got a few other items from Lowes (aircraft supply). Here's my list of goodies:

3M - Dual Respirator

Acetone (for resin cleanup)

West System Pumps (for preset mixing amounts)

West System 105 Epoxy Resin

West System 206 Slow Hardener (not to be confused with Viagra)

West System 410 Microlight Fairing Filler

Disposable Vinyl Gloves

Small Cotton Roller (to squeeze out air bubbles under fiberglass cloth)

Several "Throw away" paint brushes

Plastic Sanding Block

One box of pop-sicle sticks (to stir things up)

Several Quart mixing cups (Lowes or Grocery Store)

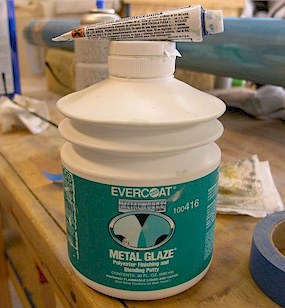

I got this Evercoat Metal Glaze from Amazon.com. It's expensive but works

nicely as a filler. WARNING: Wear a really good auto paint mask when working with this stuff.

The ingredients are very toxic.

First I scuffed up the surface of the aluminum and fiberglass tips with a scotchbrite pad

where the fiberglass tip and aluminum meet and then cleaned it off with lacquer thinner.

Then I cut a thin strip of

1.5 oz lightweight fiberglass cloth

and layed it over junction

between the aluminum and the fiberglass tip.

After putting a coat of resin on the scuffed surface, I layed the cloth down over the gap and

gently tapped it down with a brush until the cloth was totally immersed in the resin. After it

dried (usually in 24 hours), I sanded down the surface to smooth down the bumps.

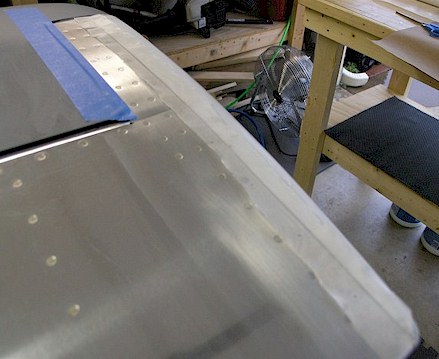

Then I mixed up a small portion of the Evercoat Metal Glaze (be sure and were a good auto paint

mask!). Then I used a plastic spreader and put an initial thin coat over the resined area. This

stuff starts setting up right after you mix it. You have maybe 3 minutes before it is unworkable.

Remember, the more you put on, the harder you have to work to sand it off later.

Wait 20 minutes after applying the Evercoat to sand to surface. Use 200-300 grit sandpaper wrapped

around a flat piece of wood. NEVER sand without the piece of wood. If you sand just using your

hand, you will get dips in the finish. Use your own judgment on the grit of the sandpaper. The

stronger the sandpaper, the more scratches you have to fill in later. Here's a picture of the

plastic spreaders. Be prepared to put to apply several

applications of the Evercoat filler until you get the results you want. Each thin application

is to fill in low spots from the previous application. If you have ever worked with taping and

bedding sheetrock, it is very similar.

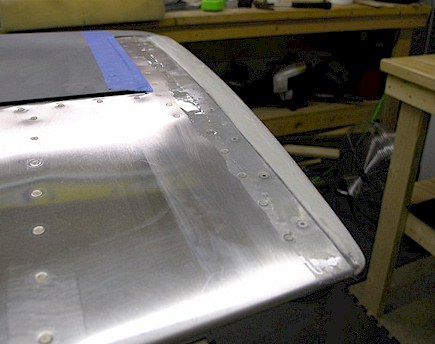

Use sandpaper wrapped around a flat piece of wood and it will give you a nice uniform surface.

Be sure and feather the filler out to the edges into the aluminum. It should look like the

picture below when you're done.

Now for the ultimate test. When you get to the point when you think it's perfect, put a coat of

primer (same stuff you've been using on your aluminum) on your creation. Then stand back with your

project between you and some outside source of light (like an open garage door). Then you can see

what a crappy a job you did! In other words, be prepared to add more filler! Just lightly sand it

down and apply more filler and sand some more. You don't have to remove the primer, just rough it up.

Repeat this process until your satisfied OR you want a beer!

Happy sanding!

|

|

|

|

HELP FOR THE HOMEBUILDER

A website designed for Van's Aircraft Homebuilders, helping them find the

information they need to build the most dynamic aircraft in the world.

|

|

|

| The "cover your butt" section |

|

This website was built to document the construction of an RV-9A in

compliance with the FAA requirements needed to certify the aircraft. Any experiences and/or comments are by

no means to be considered as instructions on how to build an RV-9A or any other aircraft. Please read our Disclosure for details.

|

|

|

This is website is owned and published by OpenAirNet, Inc. © 2015. All rights reserved.

|

|

|